Stock Deduction Strategies

By Robert Mikes on October 15, 2022

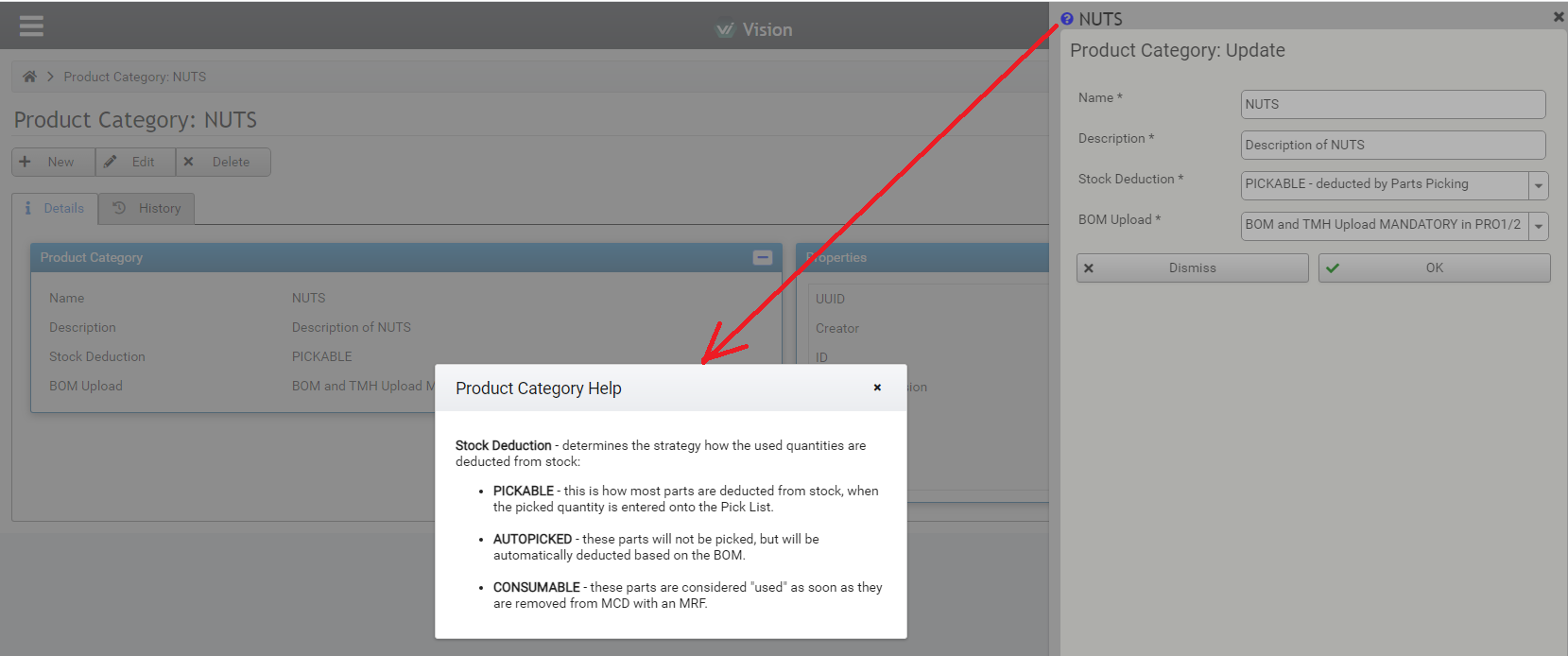

BeginnerThere are three Stock Deduction strategies that can be assigned to a Product Category.

A little information screen for these is available in Vision by clicking on the blue question mark icon:

PICKABLE

PICKABLE items are picked manually. When it is picked on the Picklist, a Storage-to-WorkOrder transaction is generated, the stock is deducted from MCD and it will be added to that Product's WIP (Work-In-Progress stock):

AUTOPICKED

AUTOPICKED items are replenished in Production Areas with MRF (this will generate Storage-to-Storage transfer, so it will still be in stock), and stock is deducted from the Production Area (based on the BOM) that corresponds to the Flow of each WOM:

| Flow | Production Area |

| PRO1 | PRO-1, but if not found there, it will be autopicked from one of the child storages under WPD (this only applies to PRO1 flow) |

| PRO2 | PRO-2 |

| Coaxial Cable | PRO-2 |

| Battery Cable v02 | PRO-2 |

| Braided Wire | PRO-1 |

| Harness Enclosure | PRO-2 |

| Overmolded Cable v02 | PRO-2 |

| Replacement Harness | PRO-2 |

| KIT | PRO-1 |

| Device Termination | PRO-1 |

| Uni-Switch Conversion | PRO-1 |

| MFA(HME) | PRO-1 |

| Overmolded Cable | WBCA |

| Tool Making | IMDT-PA |

On the Picklist the AUTOPICKED items will be disabled, so the user doesn't need to pick them (hence the name "autopicked"), except if there is not enough theoretical stock in the Production Area - in that case the item will not be disabled in the Picklist, it will become "Lacking" like any other part and it should be picked manually when it becomes available.

There will be an unavoidable variance in the number of used parts, because for example a BOM might say 100 terminals, but they might use 105 with the tool setup, crimp height test and pull strength test. We will deduct stock based on BOM qty and at the end of each month/quarter/year, HM can calculate how much more was used than the total of BOMs - that's called "yield variance".

CONSUMABLE

CONSUMABLE items are also replenished in Prod area with MRFs, but the MRF actually deducts the stock right away. So a spool of yarn or a roll of tape will be deducted from stock when it leaves MCD. We have to do this, because these parts are not on the BOM, so we don't know the quantity each WO uses.

BTW, each PRO1/2 WOM has an estimated Theoretical Yarn Cost and an estimated Theoretical Consumable Cost, but that's just a money amount, we don't know the actual quantities used.

We exchanged some messages with Jezelle today, those contained some relevant additional info: Jezelle.hmwsinc, 11:20morning Rob just want to confirm what are the items that are autopicked is it terminal and wires? And other stuff Autopicked should be the items that are on the BOM, but not picked separately for each WO. Ask engineering and production what are the items that are on the BOM and not picked per WOM, only the production area is replenished with a reel, a spool, a box of those items Some terminals should be Autopicked, others Pickable Wires all Autopicked Wire seals, dummy plugs, heat shrink Jun said Pickable, but I'm not sure about those, especially heat shrink. And then the things that are not on the BOM should be Consumable. Like tape, yarn... Again, we have those 3 categories, it should be your engineers, MCD and production people deciding what to put in each category, Titus doesn't know all your parts.