Release Notes 4.4.321

By Camille Amanda Mentzer on May 25, 2023

BeginnerInformation

| Software | HMWS Vision | Version | 4.4.321 |

| Release Date | 10-MAY-2021 | Change number | HMWS-VIS-RN-4.4.321 |

Summary

- Job List screen:

- Added several timestamp fields for tracking Work Order progress

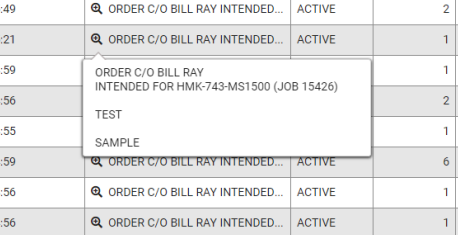

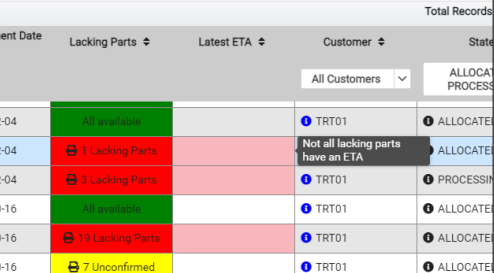

- Lacking parts field includes lacking parts count, traffic light coloring and tooltip

- Latest ETA value takes into account the ETAs of all child Work Orders

- Purchase Order field works for generated child Work Orders also

- Notes field display improvement

- Lacking parts:

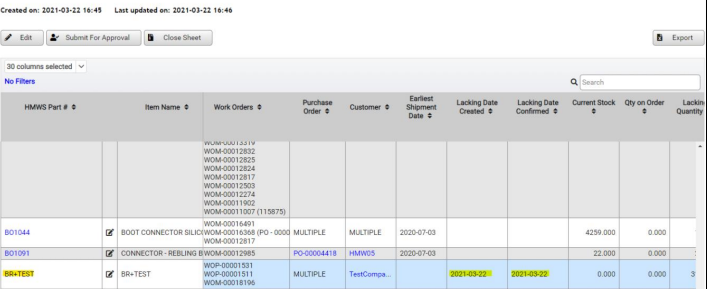

- New fields added: Lacking Parts Created and Lacking Parts Confirmed

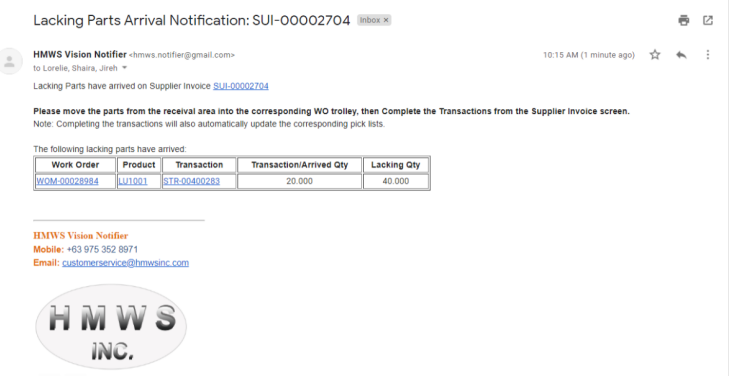

- Email notification sent when lacking parts have been received (inspected) on a supplier invoice

- Screen and report shows only products with “Parts – NOT Manufactured”

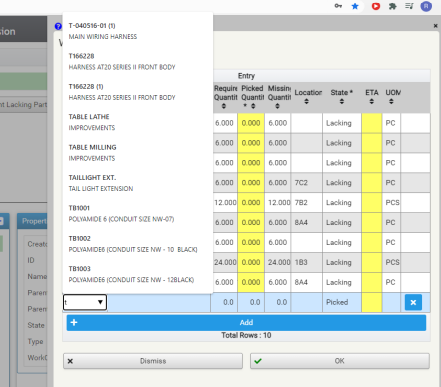

- Tooltips for Work Orders now show the flow and production state

- Parts Picking form:

- Location drop-down shows the quantity available in each location

- When adding a new row, the auto-complete field will be able to look up all products

- Full screen on tablet, limited width on desktop

- Product details:

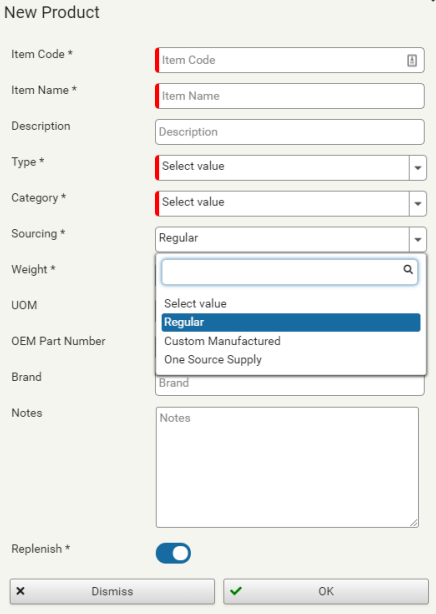

- Sourcing field added with the following values: Regular (default value), Custom Manufactured, and One Source Supply

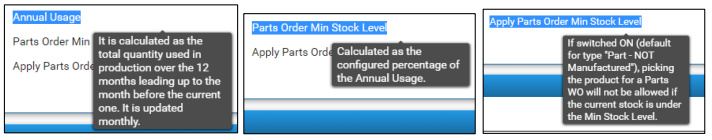

- Added explanatory tooltips for Annual Usage, Parts Order Min Stock Level and Apply Parts Order Min Stock

- Product Type can only be changed by users with “Engineering” role (not by PCCS)

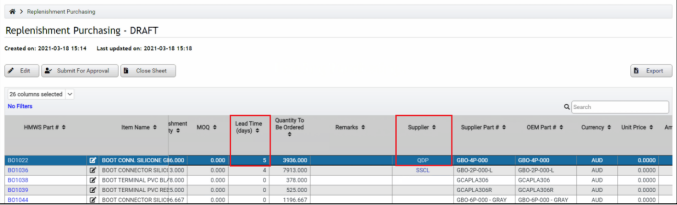

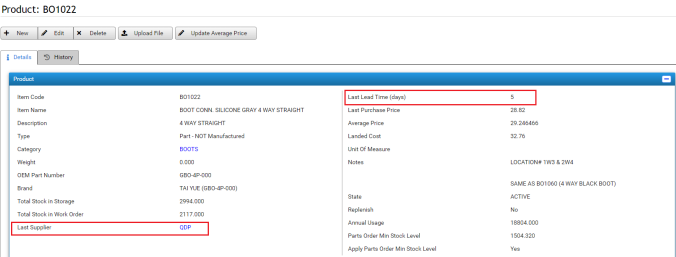

- Replenishment Purchasing screen: Supplier and Lead Time default to the last used values

- Customer Portal: added icon and count for lacking parts, tooltip for ETA

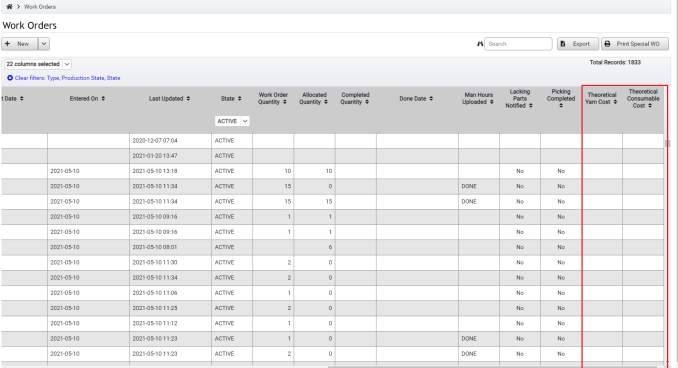

- Work Order details include the theoretical yarn cost and consumable cost

New Features / Enhancements:

- Last supplier and lead time in the Product details and list.

- Replenishment purchasing lead-time and lead supplier fields.

- Parts picking form quantity in location and all products shown.

- Lacking parts additional fields added to reservations and lacking parts screen

- Email notification sent after products have been inspected in the supplier invoice

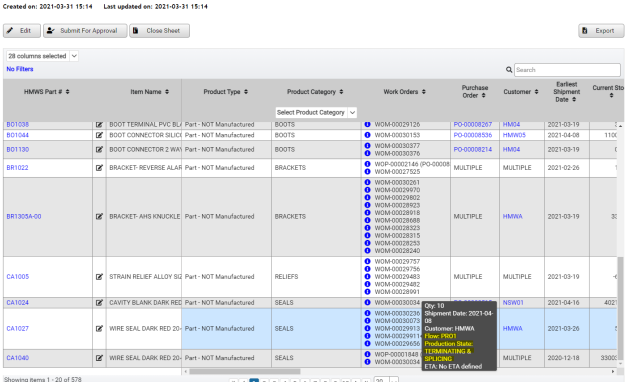

- Job List screen:

- lacking parts field with a tooltip, traffic light color background and lacking parts count Added several timestamp fields for tracking Work Order progress

- Lacking parts field includes lacking parts count, traffic light coloring and tooltip

- Latest ETA value takes into account the ETAs of all child Work Orders

- Tooltip, generated child work orders Purchase order field value.

- Lacking parts screen:

- Screen and report shows only products with “Parts – NOT Manufactured”

- Fields added to reservations and lacking parts screen

- Tooltips for Work Orders now show the flow and production state

- Parts Picking form:

- Location drop-down shows the quantity available in each location

- When adding a new row, the auto-complete field will be able to look up all products

- Full screen on tablet, limited width on desktop

- Product details:

- Sourcing field added with the following values: Regular, Custom Manufactured, and One Source Supply

- Product Type can only be changed by users with “Engineering” role (not by PCCS)

- Added explanatory tooltips for Annual Usage, Parts Order Min Stock Level and Apply Parts Order Min Stock

- Replenishment Purchasing screen: Supplier and Lead Time default to the last used values

- Customer Portal: added icon and count for lacking parts, tooltip for ETA

Supplier Invoice: email notification sent when products have been inspected

Work Order details include the theoretical yarn cost and consumable cost

Improvements/Enhancements:

- Parts picking form 100% width

- Job list added several additional fields for Tracking WO Progress and Customer Reporting.

- Job list tooltip, generated child work orders Purchase order field value.

- Job list ETA to check/retrieve the ETA of its child Work Orders

- Customer portal icon and count for lacking parts, tooltip for ETA

- Lacking parts screen and report shows only products with “Parts – NOT Manufactured”

- Tooltip in lacking parts screen for Work Orders now shows the Work Order flow and production state

- Work Order list will have the theoretical yarn cost and consumable cost.

- Product screen will have tooltips for Annual Usage, Parts Order Min Stock Level and Apply Parts Order Min Stock

- Products now have the sourcing field.

Changes

- PCCS can no longer change the Product Type. Only users with the ‘Engineering’ role are now authorized.

New Features

Job List screen

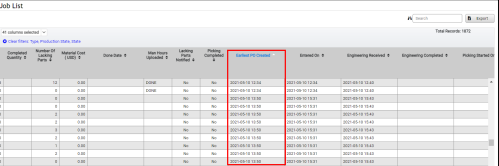

- Added several timestamp fields for tracking Work Order progress:

- Earliest PO Created shows the Entered-on Date of the PO allocated to the Work Order. If there are multiple POs, it shows the earliest entered-on date from the list of POs.

- Entered-On shows when the Work Order was created

- Engineering Received shows when the Work Order was finalized

- Engineering Completed shows when the Work Order moved to the Parts Picking step

- Picking Started On shows when the first timekeeping entry was logged for Parts Picking. If an earlier timekeeping entry is entered by a manager at a later time, this field will be updated.

- Lacking Parts Created shows when the reservations were created: for Manufacturing WOs (WOM) this is when the BOM step is confirmed done, while for Parts WOs (WOP) this is when the WO was Finalized

- Lacking Parts Confirmed is the time when the Parts Picking was done and some parts were confirmed lacking

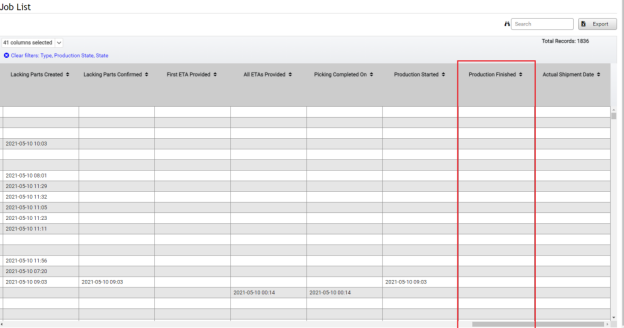

- First ETA Provided shows when an ETA was entered for the first time for a lacking part, meaning that Purchasing did the first supplier order and got ETA confirmed

- All ETAs Provided shows when an ETA was entered for all the lacking parts, meaning that all lacking parts have been ordered by Purchasing

- Picking Completed On shows when all parts have been picked, in other words there are no lacking parts remaining

- Production Started shows when WO has been moved from the Parts Picking step to the next task

- Production Finished shows when the WO was moved into PACKING step, but some flows don’t have a task with that name. Here’s the full list:

- Battery Cable, KIT, MFA (Brackets), MFA (HMA), PARTS, PRO1, PRO2, Replacement Harness: when the WO was moved into "PACKING"

- MFA (HME): when the WO was moved into "FINAL INSPECTION & PACKAGING"

- Harness Enclosure, Dummy: when the WO was moved into "DONE"

- Actual Shipment Date is taken from the Shipping Invoice. If there are multiple invoices, the latest shipment date will be shown.

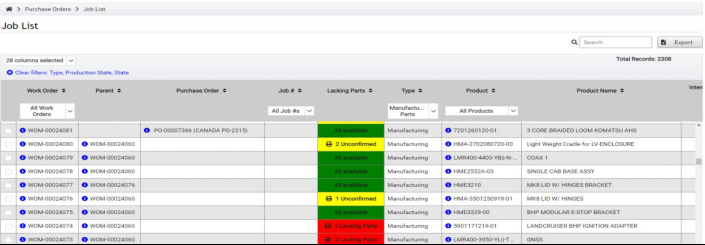

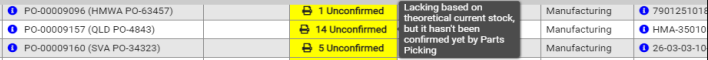

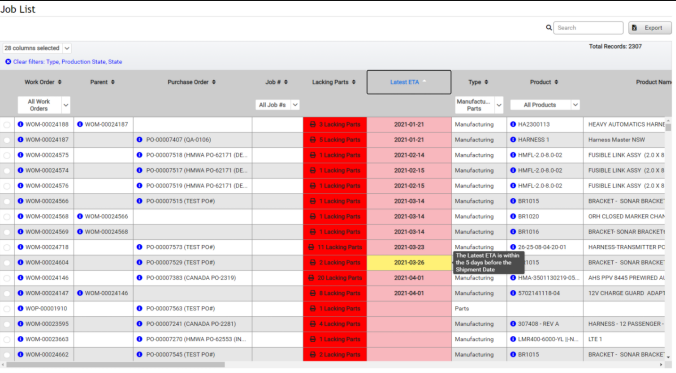

- The Lacking Parts field functions similarly to the one on the Order Summary screen (Work Order level):

- Shows the number of lacking parts, aka number of products of type “Part – NOT manufactured” that are lacking.

- It is a sum of the number of lacking parts of all of the descendant Work Orders. Descendant Work Orders are children, grandchildren etc. of a Work Order, which produce sub-assemblies needed by the parent WO. For example, a Kit WO has a child MFA(HMA) WO which also has a child Harness WO. If all of these work orders lack the same part, the number 3 will be added to the count of lacking parts for Kit (the lacking part will be counted once for each WO if it lacks from each one). A working example in the Vision system is parent WOM-00029691 (Kit), child WOM-00029729 (MFA(HMA) and grandchild WOM-00030324 (PRO1). To clarify: for example, if only the grandchild WO needs a certain part, it will only be counted only once.

- The traffic lights have tooltips to explain their colors.

- Confirmed Lacking Parts (RED):

- Unconfirmed Lacking Parts (Yellow):

- The Latest ETA field retrieves the ETA of the parent and its descendant Work Orders but filters out any deactivated child Work Orders.

- ·The ETA field has traffic-light colored backgrounds with a tooltip explaining the color

- ·If the Work Order is after parts picking, it only takes into account Picklist entries with state Lacking

- ·If the Work Order is not yet past parts picking, the ETA is based on the BOM for a Manufacturing Work Order (WOM) and based on PORs (Purchase Order rows) for Parts Work Order (WOP).

- ·The latest eta excludes manufactured parts and only takes into consideration products with type of “Parts – NOT manufactured”.

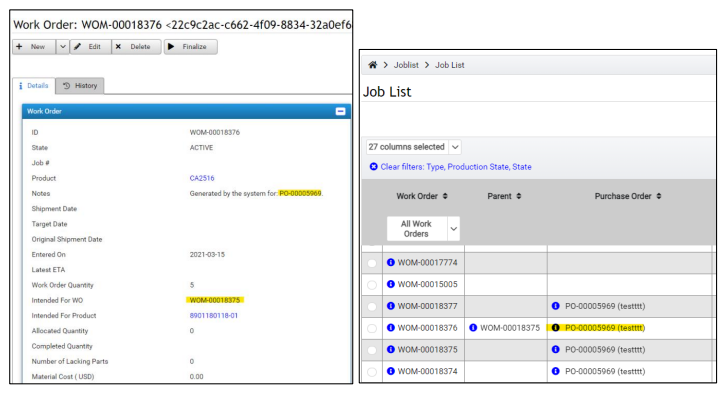

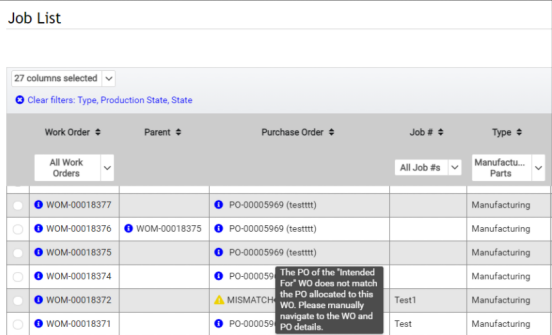

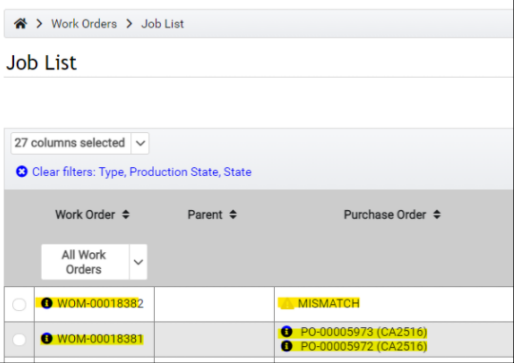

- The Purchase Order field now works for generated child Work Orders also, it will reference the PO of the parent WO:

- If the Child Work Order does not have the same allocated Purchase Order as the parent’s Purchase Order, the text “MISMATCH” will be displayed with a tooltip explaining the reason.

- If there are multiple purchase orders allocated to the child and parent work order, the job list will display the purchase orders in multiple lines.

- New clickable icon for Notes field on each Job List record that shows the multi-line notes.

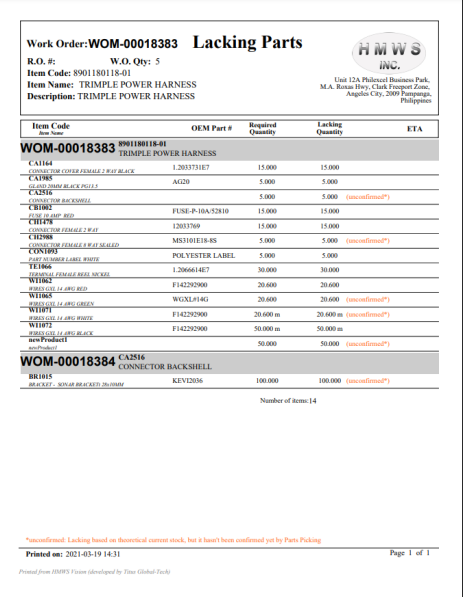

Lacking Parts

- ·The following fields have been added to the Lacking parts screen:

- Lacking Parts Created shows when the earliest reservation for that part was created: for Manufacturing WOs (WOM) this is when the BOM step is confirmed done, while for Parts WOs (WOP) this is when the WO was Finalized. If there are multiple Work Orders for this part, the date shown will be the earliest date.

- Lacking Parts Confirmed is the time when the Parts Picking was done and some parts were confirmed lacking. If there are multiple work orders for this part, the date shown will be the earliest date.

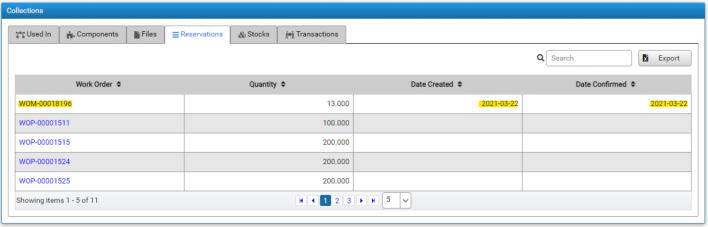

- These fields take their value from the new Date Created and Date Confirmed fields that have been added to the Reservations Collection of WOs:

- When lacking parts are received, an email notification will be Asent AFTER the products have been Inspected on the Supplier Invoice:

- Only Raw Materials (Product Type “Part – NOT Manufactured”) are shown on the Lacking Parts screen

- The Lacking Parts Report shows only products with type of “Parts – NOT Manufactured” for a Work Order and all its descendants (children Work Orders). If a part is lacking for multiple Work Orders on the same report, it will be shown once for each.

- The tooltip in lacking parts screen for Work Orders now shows the Work Order flow and production state

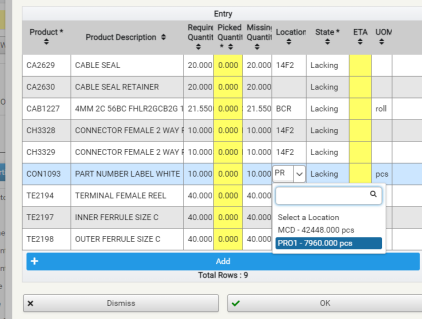

Parts Picking form

- Location drop-down shows the quantity available in each location

- When adding a new row, the auto-complete field will be able to look up all products (previously only products in the BOM were shown)

- Parts picking form full screen on tablet, limited width on desktop

Product Details

- The products will now have the Sourcing field. It is a drop down with the following values: Regular, Custom Manufactured, and One Source Supply. By default default, it will be set to “Regular”.

- In the products page, tooltips are now added for the Annual Usage, Parts Order Min Stock Level and Apply Parts Order Min Stock.

Replenishment Purchasing

- The Supplier and Lead Time fields will default to the last used values:

- The Last Supplier and Last Lead Time are saved in the Product details:

Customer Portal

- An icon for lacking parts and the count for Confirmed and Unconfirmed lacking parts has been added to Lacking Parts field.

- Tooltip on the Latest ETA to explain why it is red.

Work Order

- Theoretical Yarn cost and Theoretical Consumable cost is now shown in the Work Order list

New Feature Details

- Products

- Added the following fields based from the generated Supplier POs:

- Last Supplier

- Last Lead Time (days)

- Replenishment Purchasing screen

- ·When generating the rows of products needed to be replenished. The Replenishment table will show as a default The Supplier and Lead Time and fields Supplier will default to the last used values that is saved in a product.

- The Last Supplier and Last Lead Time are saved in the Product details:

- Parts Picking form

- Shows the quantity in location drop down of the Parts Picking form

- ·All Products now listed/available when adding a product in the parts picking form (previously only products in the BOM were shown).

- Lacking Parts

- The following fields have been added to the Reservations Collection.

- Date Created – This is when a reservation is created for a product.

- Date Confirmed – This date is filled up when a Work Order is after the parts picking step and it still has a quantity for the reservation.

- ·The following fields have also been added to the Lacking parts screen.

- ·Lacking Parts Created – This is based on when a reservation for a Product is created for a Work Order. If there are multiple Work Orders for this part, the date shown will be the earliest date.

- ·Lacking Parts Confirmed – This is based when a Work Order is after the parts picking step and still has lacking parts. Similar to the date created, if there are multiple work orders for this part, the date shown will be the earliest date.

- ·When lacking parts arrive, an email will be sent AFTER the products have been Inspected in the supplier invoice.

- ·Show only Raw Materials (Product Type – “Part – NOT Manufactured”).

- Job List

- The lacking parts field functions the same as what is in the Order Summary screen (Work order level).

- It is the count of unique products only of type “Part – NOT manufactured”.

- The number will count the lacking parts for all of the descendant Work Orders. Descendant Work Orders are those that depend on another Work Order. For example, a kit Work Order depends on an MFA(HMA)Work Order which also depends on a Harness Work Order. If these separate descendant Work Orders lack the same part, it will be counted thrice. A working example in the Vision system is WOM-00029691 (Kit Work Order) has dependencies which are WOM-00029729 (MFA(HMA) Work Order) and WOM-00030324 (PRO1 Work Order).

- The traffic lights have tooltips to explain their colors.

- Confirmed Lacking Parts (RED)

- Unconfirmed Lacking Parts (Yellow)

System Enhancements and Improvements

- Parts picking form width is set to 100%. (Enable better usability for Tablets & MCD pickers)

- Job List

- New clickable icon for Notes field on each JobList record that shows multi-line note.

- For generated child Work Orders, the Purchase Order field will contain the parent’s PO number.

- If the Child Work Order does not have the same allocated Purchase Order with the parent’s Purchase Order. The text will be displayed in the Purchase Order Field with a tooltip explaining the message.

- If there are multiple purchase orders allocated to the child and parent work order. The job list will display the purchase orders in multiple lines.

- The latest ETA field retrieves the ETA of the parent and its descendant Work Orders but filters out any deactivated child Work Orders.

- The ETA field has traffic-colored backgrounds with a tooltip explaining the color

- If the Work Order is after parts picking, it only takes into account Picklist entries with state Lacking

- If the Work Order is not yet past parts picking, the ETA is based on the BOM for a Work Order manufacturing and PORs (Purchase Order rows) for Work order parts.

- The latest eta excludes manufactured parts and only takes into consideration products with type of “Parts – NOT manufactured”.

- The Earliest PO Created shows the entered-on Date of the PO allocated to the Work Order, if there are multiple POs, it shows the earliest entered on date from the list of POs.

- The Entered-On date is also shown in the tooltip of a Purchase Order.

- The Entered-On date of a Work Order is now shown in the Job List

- The Engineering Received date is the date when the Work Order is finalized.

- The Engineering Completed date is the date when the Work Order moved to the Parts Picking step.

- The Picking Started date is the date and time when the first logged time is entered for Parts Picking. If an earlier time is logged, this field will be updated.

- The Lacking Parts Created is the same date seen on the Lacking parts screen.

- The Lacking Parts Confirmed is the same date seen on the Lacking parts screen.

- The First ETA provided is the date when an ETA is entered for the first time for lacking parts.

- The All ETAs provided is the date when an ETA is entered for all the lacking parts.

- The Picking Completed On is the date when everything for the Work Order is picked and there are no more lacking parts.

- The Production Started is the date when the Work Order moves into the state after parts picking.

- The Production Finished date is updated based on the following:

- Harness Enclosure, Dummy: when it goes to "DONE"

- Battery Cable, KIT, MFA (Brackets), MFA (HMA), PARTS, PRO1, PRO2, Replacement Harness: when it goes to "PACKING"

- MFA (HME): when it goes into "FINAL INSPECTION & PACKAGING"

- The Actual Shipment Date is the date that comes from Shipping Invoice. If there are multiple invoices, the latest shipment date will be used.

- Customer Portal

- An icon for lacking parts and the count for Confirmed and Unconfirmed lacking parts has been added to Lacking Parts field.

- Tooltip on the Latest ETA to explain why it is red.

- Lacking Parts

- Report

The lacking parts report shows only products with type of “Parts – NOT Manufactured” for a Work Order and all its descendants (children Work Orders). If a part is lacking for multiple Work Orders on the same report, it will be shown once for each.

- The tooltip in lacking parts screen for Work Orders now shows the Work Order flow and production state

- Work Order

- Theoretical Yarn cost and Theoretical Consumable cost is now shown in the Work Order list.

- Products

- In the products page, tooltips are now added for the Annual Usage, Parts Order Min Stock Level and Apply Parts Order Min Stock.

- The products will now have the Sourcing field. It is a drop down with the following values: Regular, Custom Manufactured, and One Source Supply

Production Issues Fixed

- Fix Employee or Contact Person to deactivate their own account (375)

- Show Purchase Order for Work Orders with Intended for in the Job List (382)

- Some Work Orders get stuck on uploading man hours (383)

- Improved error message in the Dedicated timekeeping screen to redirect the user to the Work Order screen if their time is manually updated (388)

- Stock take. Some products imported in the stock take file are not updated (390)

- Splitting a Work Order does not automatically deactivate the parent (391)

- Adding of a Purchase Order Row to a Purchase Order with a special character in the notes causes an error (392)

- Adding of a Purchase Order Row to a Purchase Order with a special character in the notes causes an error (392)

- Unable to deactivate a Work Order (394)

- A storage transaction has a direction of Supplier Invoice to Storage, but it does not have a supplier invoice linked to it (396)

- Work Order ID overflows from the pick slip (398)

- Wrong recipients for the Purchasing’s email for approval (399)

- Update email recipients removing specific personnel from the list of recipients. (400)

- Invalid location error in Parts picking (407)

Was this article helpful?

More articles on Release Notes