Release Notes 5.1

By on December 8, 2022

BeginnerInformation

HMWS Vision Release Update 2021

| Software | HMWS Vision | Version | 5.1 |

| Release Date | Nov. 30 2022 | Change number | HMWS-VIS-RN-5.1 |

Supplier Orders: ETA fields are added to SPO Rows

Work Orders: ETAs moved from Pick List to Reservations

Bulk Processing of ETAs in SPO Rows

Repeat Orders Handling Improvements

Re-use man-hours for repeate orders

WO Man Hours Last Uploaded Timestamp and Circuit Engineering Version now visible to all employees

Remove default notes forgenerated WOs25

Show production state for WO Children

Print Flow onto inspected SUI transactions

Run Fat Finger Check upon SUI Inspection

Products will be set to Replenish if the total usage goes above threshold

Show Supplier in Price History of Products

Attachment versioning based on file name

Show Supplier in Price History of Products

New Features and Enhancements ETA Handling Improvements

https://titus.erpnext.com/app/issue/TKT-00010

Supplier Orders: ETA fields are added to SPO Rows

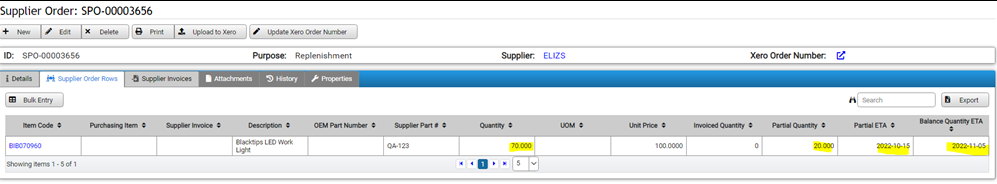

New ETA fields are added to SPO line items.

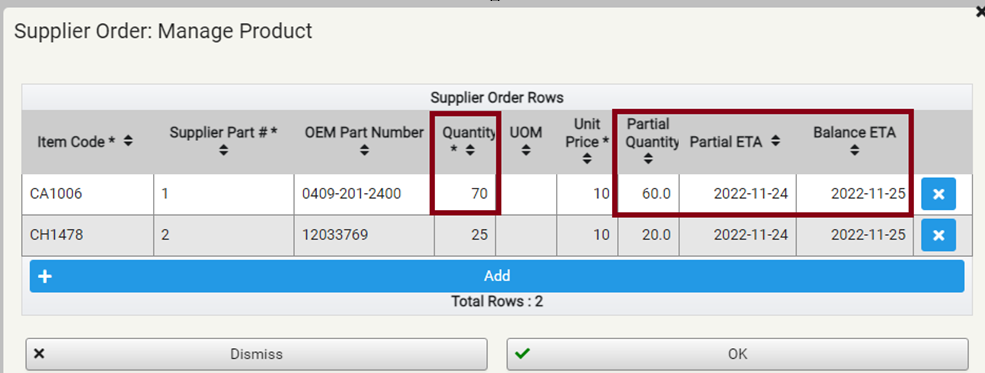

- Balance Quantity ETA: This is the “main” ETA field. If the ordered quantity is delivered in one single batch, this is the only field that needs to be filled out. However, if the delivery is made in multiple batches, this ETA value applies to the quantity remaining after the previous delivery, i.e. to the “balance quantity”.

- Partial Quantity and Partial ETA – These values apply to the first partial delivery. These only need to be filled out if the ordered quantity will be delivered in multiple separate batches.

Figure 1: Supplier Order Rows bulk entry with new ETA fields

In the above example, out of the total ordered quantity of 70 pieces, a partial delivery of 60 is expected on 2022-11-24 and the remaining quantity of 10 is expected on 2022-11-25.

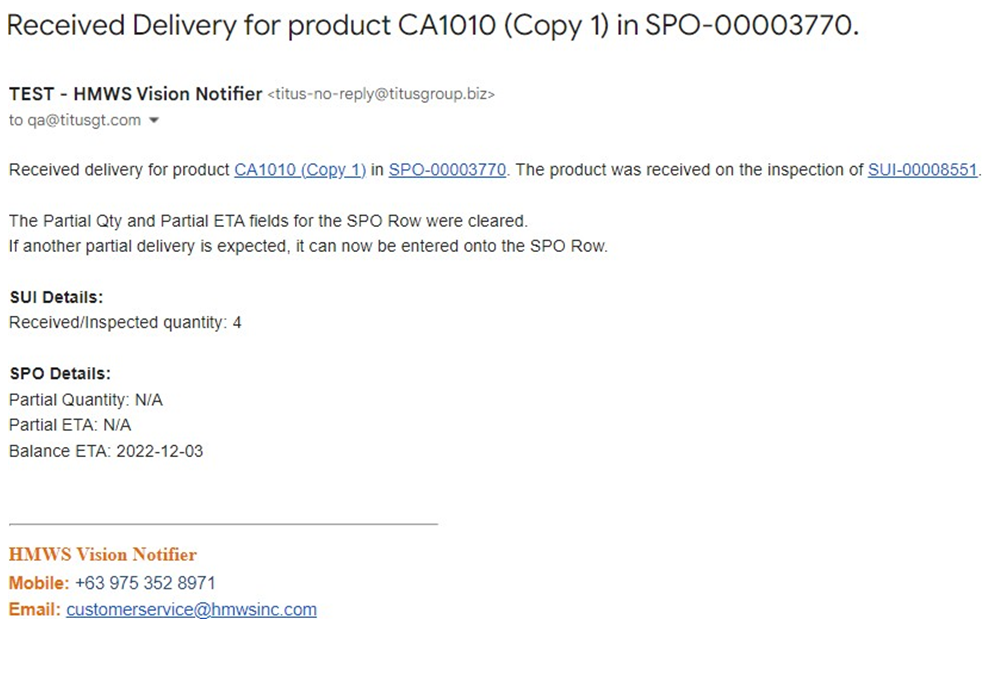

- ·The Partial Quantity and Partial ETA fields will be cleared once a partial delivery of the part is inspected on a Supplier Invoice linked to this SPO. These fields will be cleared even if the inspected/accepted quantity is less than or greater than the Partial Quantity entered by the user!

- ·When a SUI is inspected and affects the SPO Row’s Partial Quantity and Partial ETA field, an email alert will be sent to the user who inspected the SUI together with a list of configurable recipients.

- ·As can be seen in the email, if more than two deliveries are expected for an SPO, after a partial delivery is inspected, the Partial Quantity and Partial ETA values of the next partial delivery can be entered in the now cleared fields.

Figure 2: Sample email after inspecting an SUI

Note:

ETAs can be set for all SPO Rows, not just the rows that are lacking. This new feature makes it possible to set ETAs for parts that are close to depletion, but not yet lacking, which are showing up on the Stock Depletion report as 10 or 30 days away from depletion.

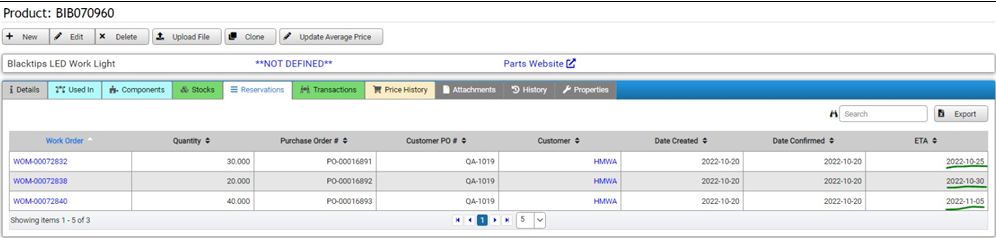

Work Orders: ETAs moved from Pick List to Reservations

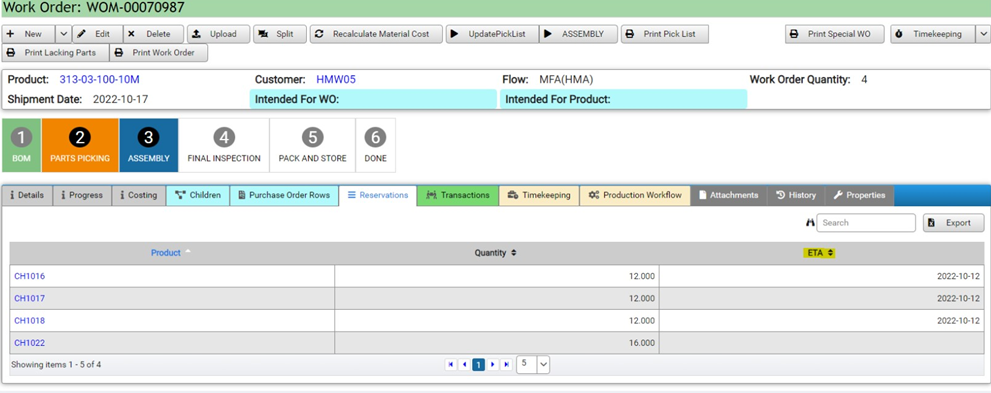

The ETAs of the parts required for a Work Order are now moved from the pick list to the reservations.

Figure 3: Work Order with ETA in reservations

Automatic update of WO ETAs

Vision now automatically calculates the ETAs for the lacking parts in each WO based on the ETAs entered into the SPOs.

- ·The ETAs are assigned to reservations according to the first-come-first-served (FIFO) strategy based on Entered On date of the WOs. So the WO that was first entered into Vision will get the first delivery of parts.

Figure 4: Supplier Order Row: Set ETA for part

Accordingly, the manually entered ETA fields in the following screens are now disabled:

- ·Work Order -> Pick List

- ·Lacking Parts sheet

- ·Lacking Parts Bulk Update

Figure 5: Product Reservation: ETA updated

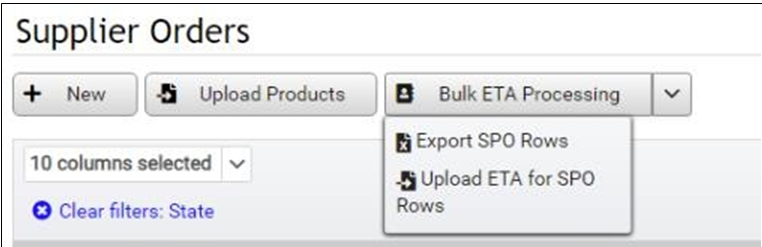

Bulk Processing of ETAs in SPO Rows

The manual update of ETAs on each individual SPO is possible via the [Bulk Entry] button that is on the Supplier Order Rows tab (see Figure 4).

However, to make the update more efficient, we have added a [Bulk ETA Processing] button to the Supplier Orders screen:

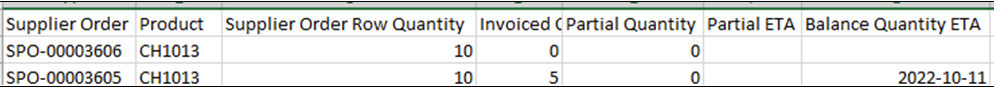

- ·Clicking [Export SPO Rows] downloads a template that can then be used to update the ETAs for each SPO Row.

- ·The SPO rows exported are from active SPOs where the ordered quantity is greater than the total accepted/inspected quantity on SUIs linked to that SPO.

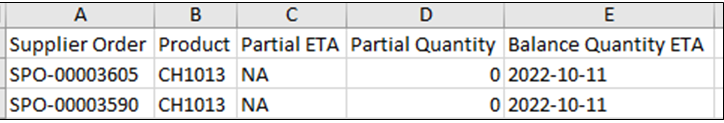

- ·After the user fills in the ETA values, the excel sheet can be uploaded using the [Upload SPO Rows] button.

- ·Vision will update the ETA values in those SPOs and automatically re-allocate ETAs to reservations.

Figure 6: Supplier Order Bulk ETA button

Figure 7: Supplier Order Export SPO Rows

An email is also sent based on the configured list of recipients with the results of the bulk processing.

Figure 8: Supplier Order upload result file

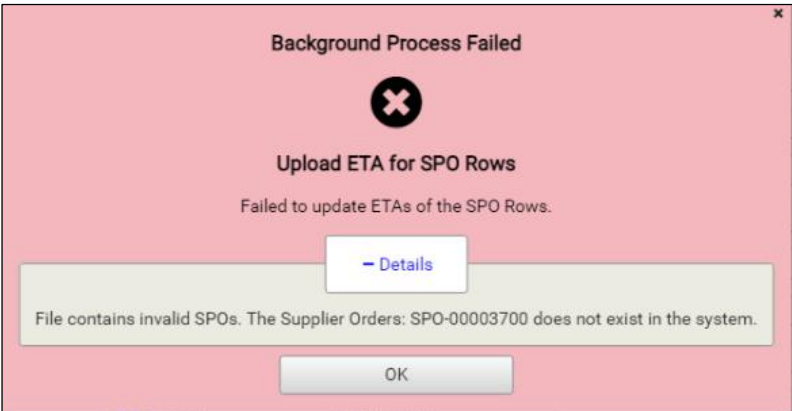

Validations are also in place whenever a user has entered an incorrect value. The following are the validations in place:

- ·File contains invalid SPOs

- ·File contains invalid products

- ·File contains products that are not in the SPO

Figure 9: Sample SPO Bulk Update ETA error message

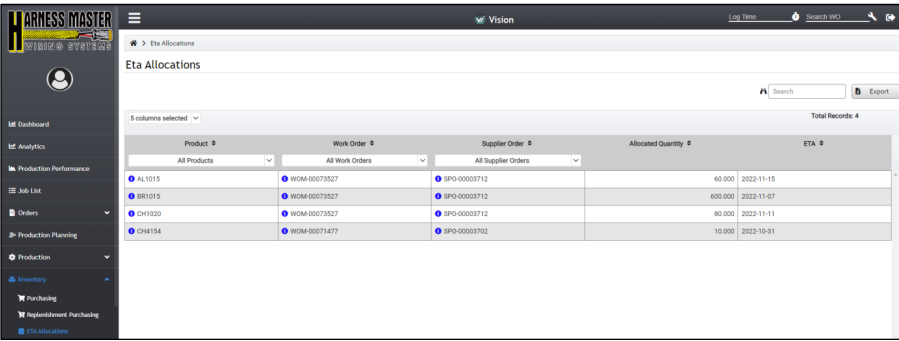

ETA Allocations screen

A new screen is added in Inventory – ETA Allocations that shows for each reservation (Product-WorkOrder pair) how much of the quantity (Allocated Quantity) will be delivered by which SPO (Supplier Order) and when (ETA). When there are new ETAs allocated, the list shown will be updated with the new ETAs.

Figure 10: ETAs Allocation List

Repeat Orders Handling Improvements

Re-use man-hours for repeat orders

https://titus.erpnext.com/app/issue/TKT-00008

A Repeat Order is defined as a Work Order for which we can find in the system a previous Work Order that has all of the following characteristics:

- same Flow

- same Product

- uploaded man-hours (XML file), which were generated from a Circuit Engineering sheet of the latest version (version 140)

To save engineering time, upon Finalizing a Repeat Order (RO), Vision will automatically:

- ·re-use the BOM from the previous order

- ·pro-rate the Theoretical Man-Hours from the previous order

- ·pro-rate the Theoretical Consumable Cost from the previous order

Pro-rating is done based on the quantity of the two orders with the following formulas:

- ·Repeat Order Man-Hours = (Previous Man-Hours / Previous Quantity) × Repeat Order Quantity

- ·Repeat Order Consumable Cost = (Previous Consumable Cost / Previous Quantity) × RO Quantity

For example, if the quantity of the previous work order is 3 and the estimated man-hours for a certain step were 30 hours, while the quantity of the Repeat Order is 5, the computation will be:

- ·Repeat Order Man-Hours = (30 / 3) × 5 = 50 hrs

- A warning message will be displayed to the user in the following scenarios:

- ·No uploaded file was found for the same product and flow

- ·The last uploaded file for a previous WO with the same product and flow is not an XML file

- ·The last uploaded XML file does not match the latest circuit engineering version

- ·An unexpected error occurred while processing the last uploaded file

Figure 11: Sample warning message

As can be seen from the text in Figure 11, when such a warning is shown, the Work Order will have to go through full engineering in the usual way, i.e. a Circuit Engineering sheet will have to be filled out and the generated XML file will have to be uploaded.

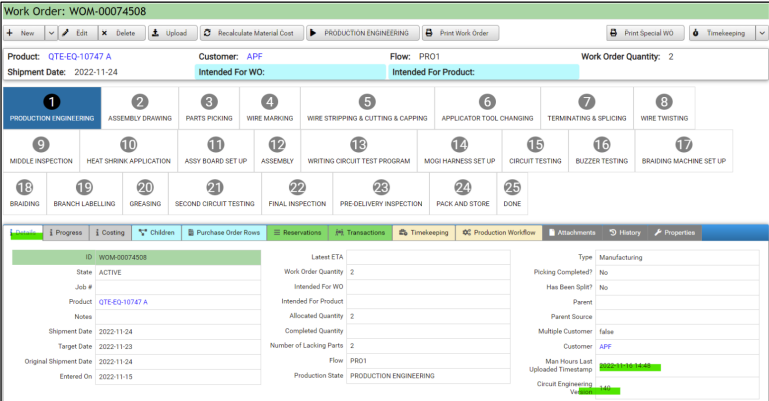

However, if the Repeat Order was successfully handled by Vision (BOM re-used, man-hours and consumable costs pro-rated), the Man Hours Last Uploaded Timestamp and Circuit Engineering Version fields of the Work Order will contain values (see Figure 12). The presence of such values can be used as an indication that there is no need for full engineering, but the drawing and the Circuit Engineering sheet still needs to be printed by a clerk. Consequently, the WO still needs to go through the PRODUCTION ENGINEERING step in Vision, but there is no need for the involvement of an engineer.

WO Man Hours Last Uploaded Timestamp and Circuit Engineering Version now visible to all employees

https://titus.erpnext.com/app/issue/TKT-00224

The Man Hours Last Uploaded Timestamp and Circuit Engineering Version field of the Work Order were previously only visible for employees with Finance roles because they were located on the Costing tab. These fields are now moved to the Details tab to be visible for all employees.

Figure 12: Work order details with Man hours uploaded and circuit engineering version on details tab

Work Orders

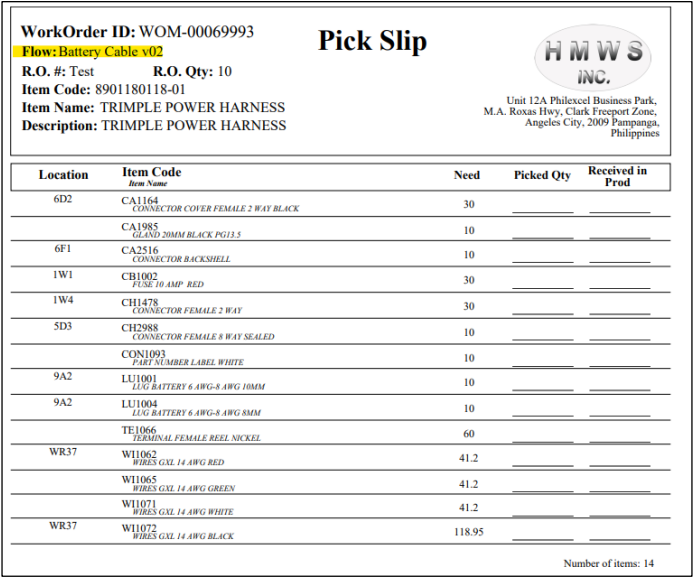

Print Flow onto Work Orders

https://titus.erpnext.com/app/issue/TKT-00029

The work order flow is now displayed when printing a work order.

Figure 13: Work order print file

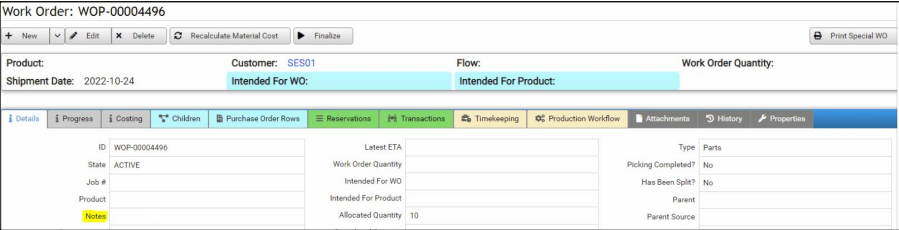

Remove default notes for generated WOs

The default “Generated by the system for …” notes added automatically for generated Work Orders will not be added anymore.

Figure 14: Sample Work Order generated from a PO without notes

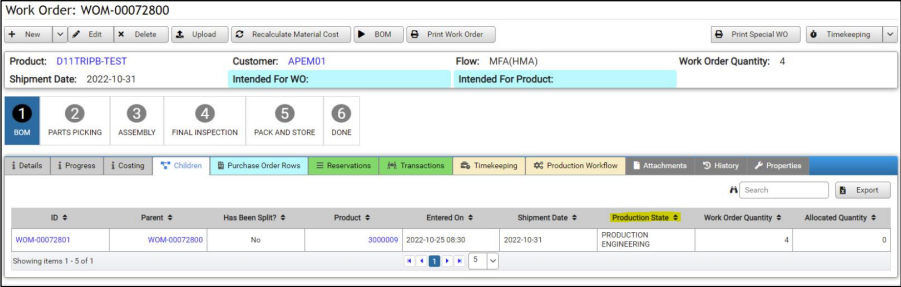

Show production state for WO Children

https://titus.erpnext.com/app/issue/TKT-00040

The production state of each child work order will now be shown on the Children tab of the parent WO.

Figure 15: Work Order children with production state

Supplier Invoices

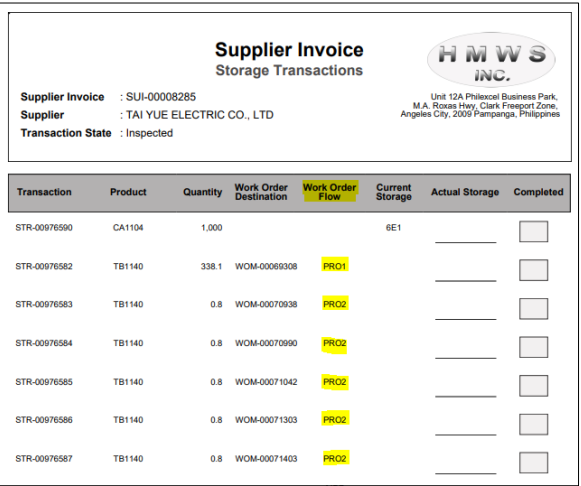

Print Flow onto inspected SUI transactions

https://titus.erpnext.com/app/issue/TKT-00030

The work order flow is now displayed when printing inspected transactions.

Figure 16: Supplier invoice print

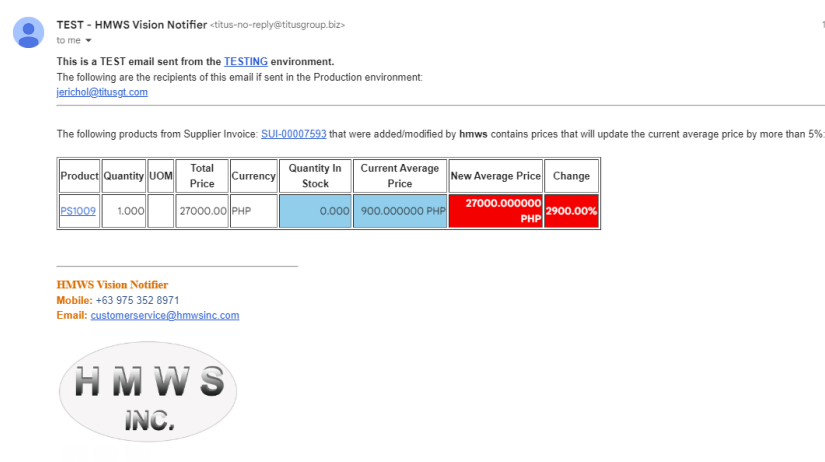

Run Fat Finger Check upon SUI Inspection

The Fat Finger Check validation was added to the SUI Inspection step. The same validation is now applied3 times:

- ·The first time is on the SPO and second time when the SUI is entered. Now it will also be applied when Inspecting the SUI.

- ·The validation is the same: if the entered price would change the Average Price by more than 5%, a warning popup is displayed to confirm that the user still wants to proceed.

Figure 17: Sample validation popup if the average price would be changed more than 5%

- ·If the user clicks [Yes],an email alert is sent to a pre-configured list of recipients.

Figure 18: Sample email with price validation

Products

Products will be set to Replenish if the total usage goes above threshold

https://titus.erpnext.com/app/issue/TKT-00012

If the Product’s replenish field is Order as Required, it will automatically be changed to Replenishif the usage of the product for 7 months (configurable) is above a threshold.

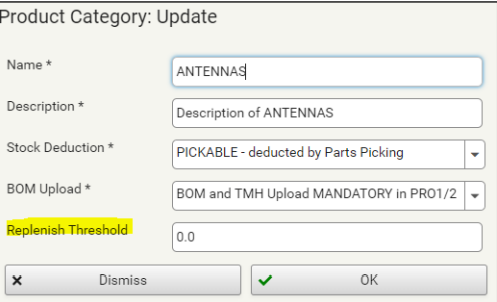

The threshold is defined for each Product Category in a new field: Replenish Threshold. This field is only editable for users with the PurchasingManager role. It is also included in the bulk processing.

Figure 19: New field replenish threshold in product category

Show Supplier in Price History of Products

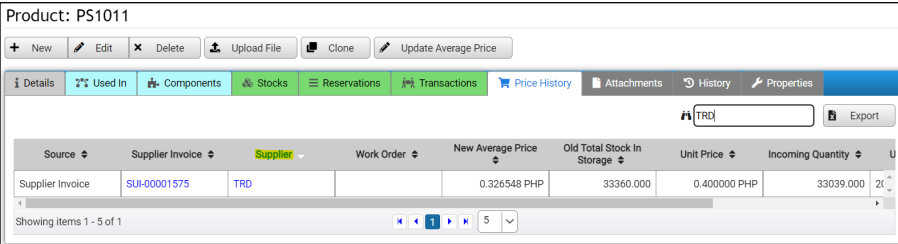

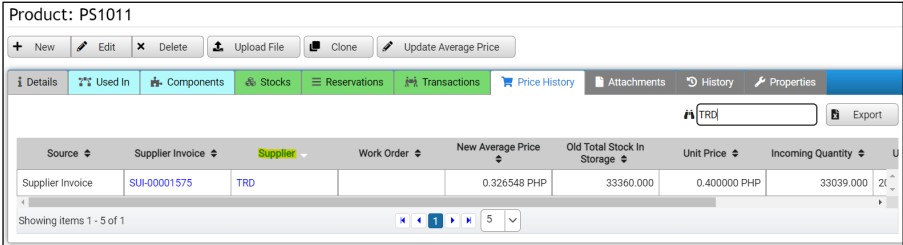

https://titus.erpnext.com/app/issue/TKT-00198

The Supplier is now shown in the price history of each product. The supplier indicated comes from the Supplier Invoice shown in the price history.

Figure 20: Supplier in Price History

Attachment versioning based on file name

When a file is attached to a Product, Vision checks if there was a previous attachment with the exact same filename:

- ·If no, a new attachment is added, therefore a new file will be shown in the Attachments tab.

Figure 21: Product attachments – multiple files

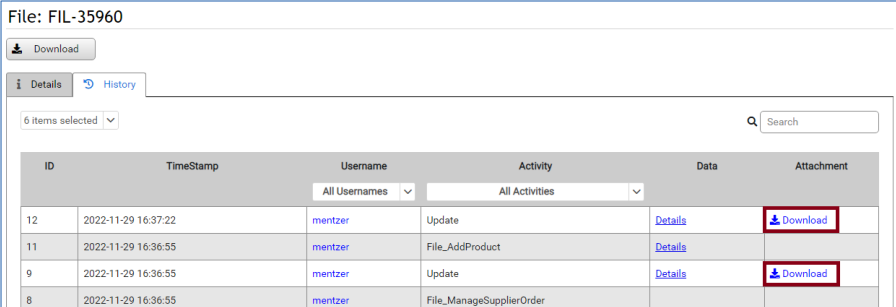

- ·If yes, the newly uploadedfile will “override” the existing attachment, i.e. a new versionof the existing file is created. This can be seen in the History of that File entity, where the previous version can also be downloaded.

Figure 22: File history

Show Supplier in Price History of Products

https://titus.erpnext.com/app/issue/TKT-00198

The Supplier is now shown in the price history of each product. The supplier indicated comes from the Supplier Invoice shown in the price history.

Figure 23: Supplier in Price History

Purchase Orders

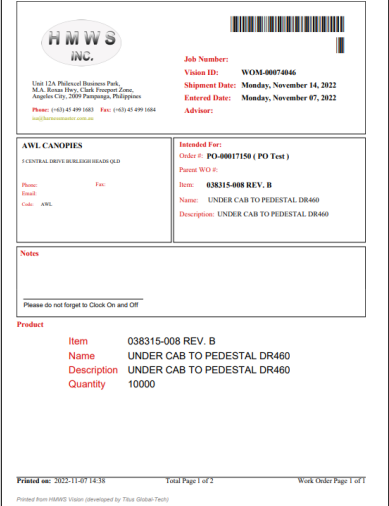

Bulk Print Work Orders

https://titus.erpnext.com/app/issue/TKT-00035

A new [Print Work Orders] button was added to thePO Details screen.This button will print all the Work Orders associated with the PO, including all descendant (child, grandchild...) WOs.

Each work order will have its separate page in the generated PDF. If a Work Order has several pages, a proper numbering label will be displayed on the lower right corner to avoid misplacing sheets. It will contain two page numberings:

- ·The page number of each Work Order in the document: Work Order page x of x

- ·The page number and total number of pages of the document: Total Page x of x. Below is a detailed list of which Work Orders will be included and excluded:

- ·Will include:

o Finalized WOs

o WOs that have allocated PORs from the PO

o Child WOs from split

o Child Generated WOs (if the Intended-for-WO is not Deactivated)

o Split Child Generated WOs (if the Intended-for-WO is not Deactivated)

- ·Will not include:

o Draft (un-finalized) WOs

o Unallocated WOs

o Deactivated WOs

o ACTIVE Child Generated WOs (if the Intended-for-WO is Deactivated)

Figure 24: Print work order sample from PO

More articles on Release Notes